Our Precision Sheet Metal Services cater to a wide array of industries, from HVAC and electronics to industrial machinery. Leveraging advanced CAD tools and extensive material expertise, we deliver customized solutions, including enclosure designs, DXF files, reverse engineering, and comprehensive engineering documentation. Whether you’re looking to optimize existing designs or develop new products, our team ensures precision, efficiency, and compliance with all industry standards.

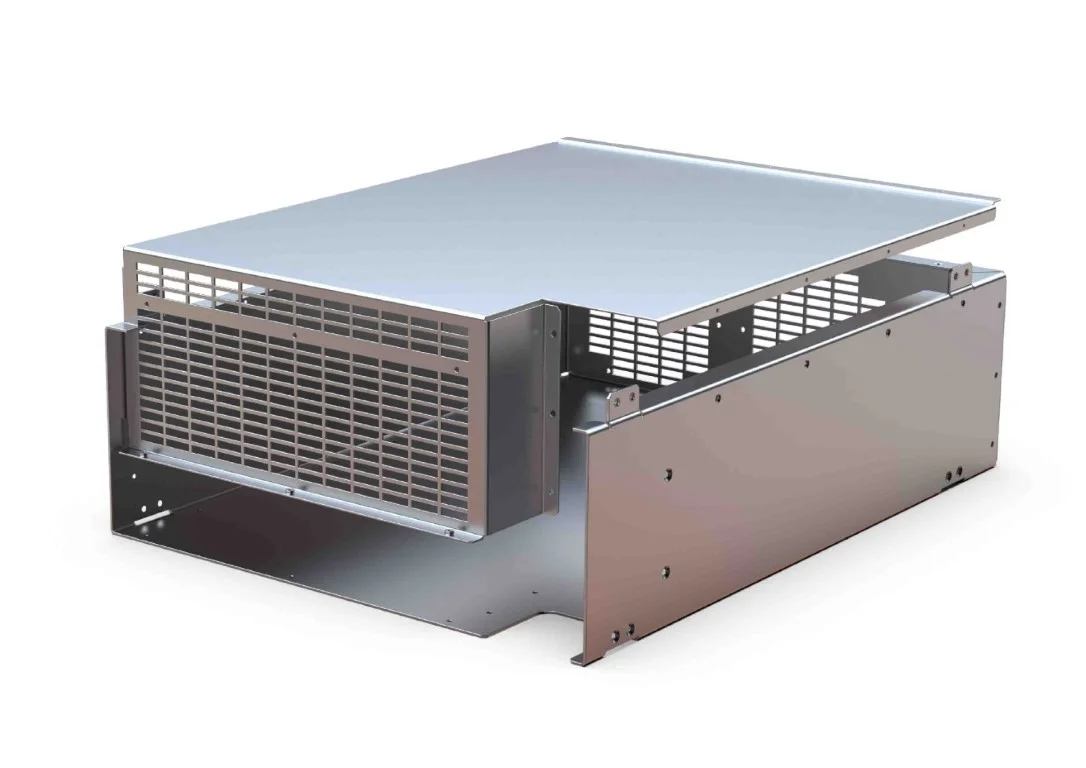

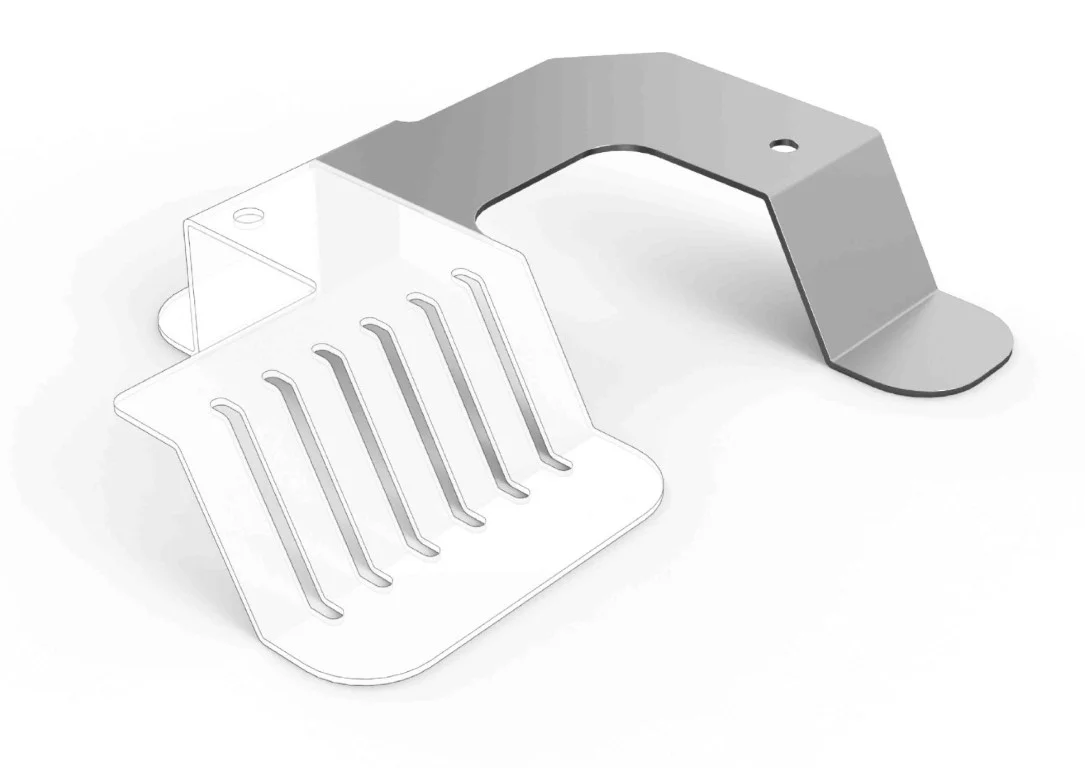

Specializing in sheet metal solutions for the HVAC industry, we design and fabricate ducts, vents, and housings that meet specific environmental and regulatory requirements. Our precise fabrication processes ensure efficient airflow and system performance, reducing energy costs and improving indoor air quality.

Our enclosure designs are tailored to protect sensitive machinery and electronic components from environmental factors and operational stresses. We provide innovative designs that enhance accessibility, ensure safety, and integrate seamlessly with the aesthetic and functional needs of your overall system.

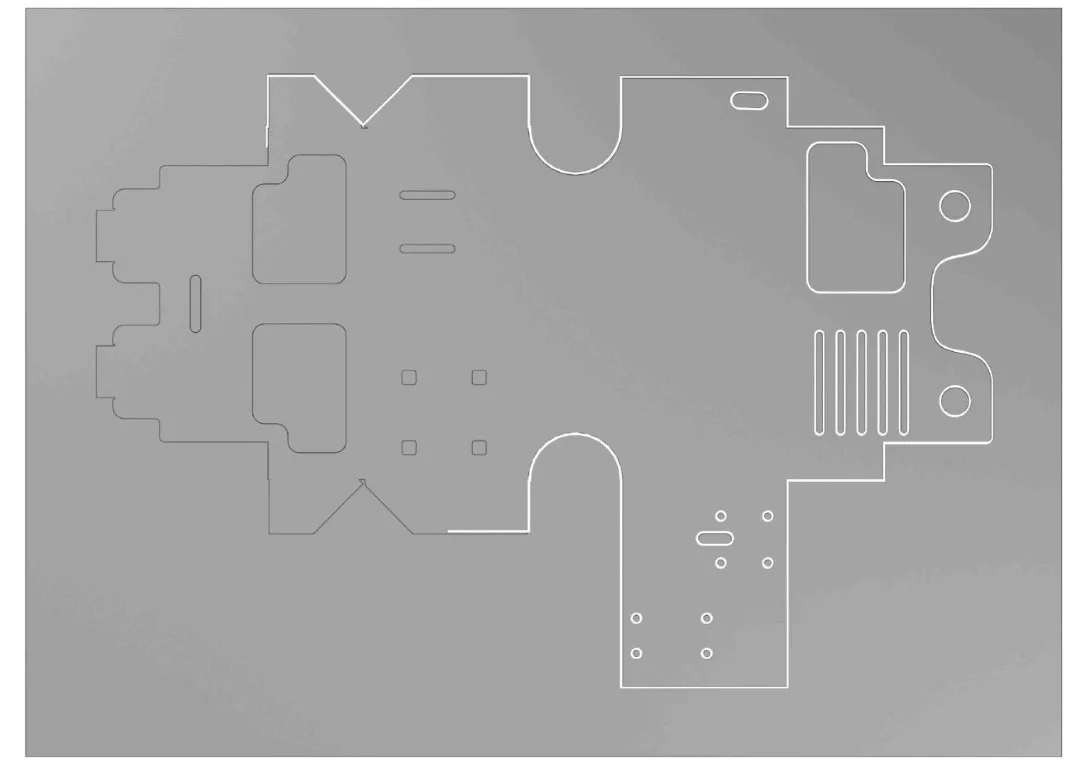

We generate detailed DXF files to facilitate precision cutting of sheet metal components. These files are optimized for CNC machines, ensuring high accuracy and repeatability in production, which is crucial for maintaining quality across large batches.

Our reverse engineering services allow you to replicate or improve existing sheet metal parts. We analyze physical parts to create accurate CAD models and drawings, enabling enhancements in design, material usage, and cost-effectiveness.

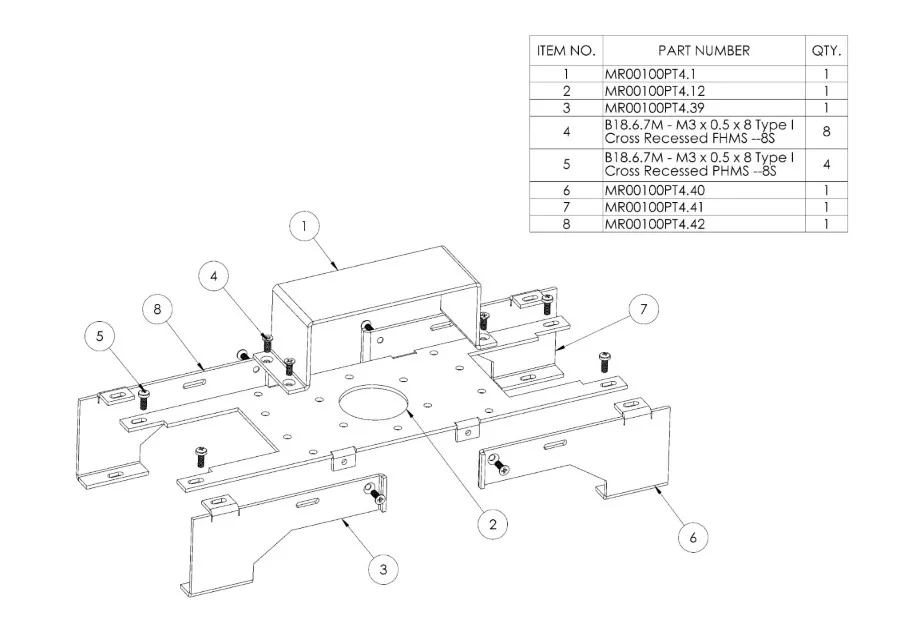

Our engineering services include the creation of detailed drawings and a complete Bill of Materials (BOM). These documents are essential for accurate fabrication, assembly, and inventory management, streamlining the manufacturing process and reducing the potential for errors.

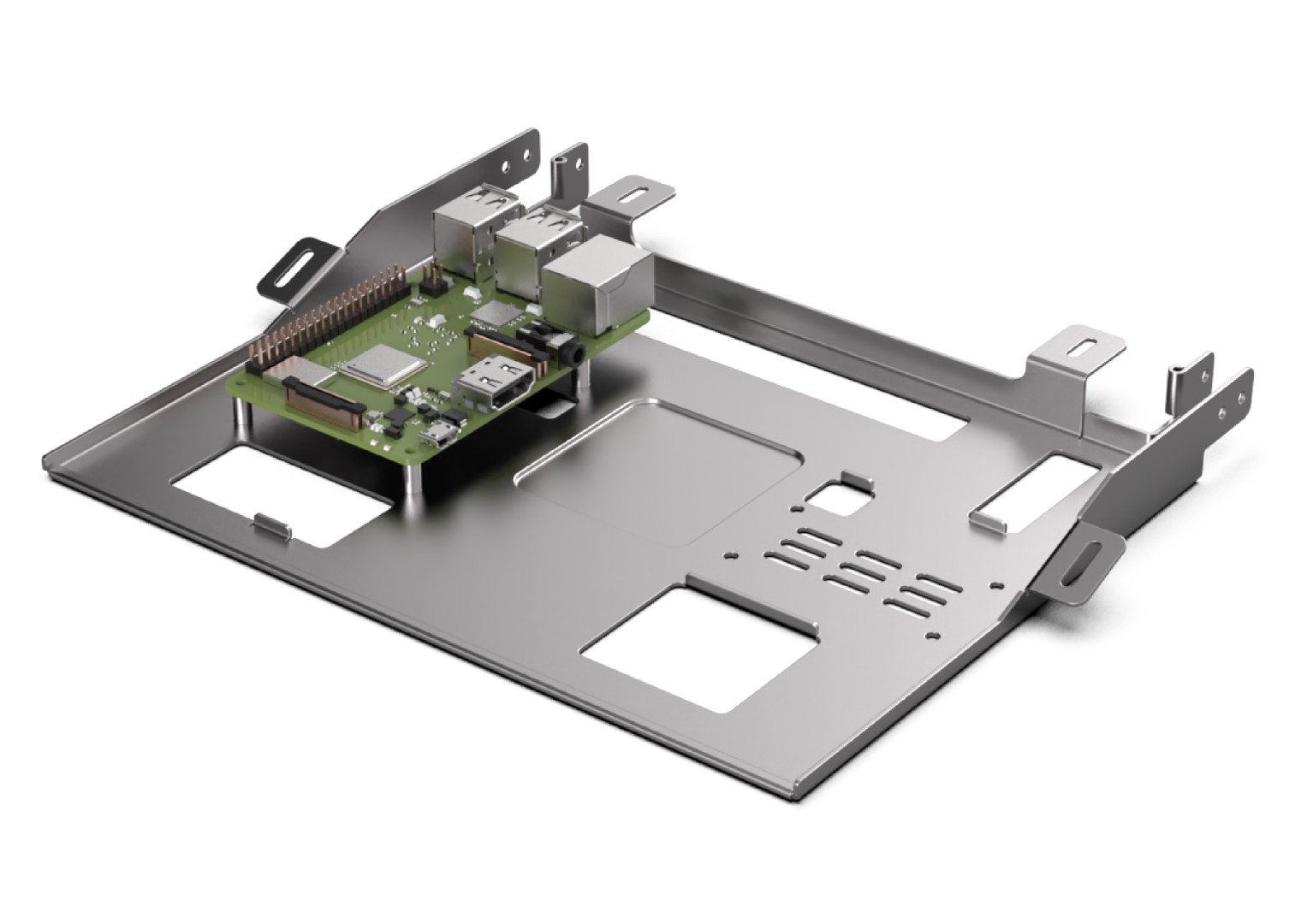

We design and fabricate chassis for various applications, from heavy industrial machinery to delicate electronic devices. Our chassis designs focus on structural integrity, thermal management, and ease of assembly, ensuring that they meet the rigorous demands of operational and environmental conditions.